A port strike in Hamburg. A typhoon rerouting Pacific shipping lanes. A driver shortage across the Midwest – all hitting the same week. Your TMS fires alerts. Your ERP flags exceptions. Dashboards light up red. But here’s the question nobody’s spreadsheet can answer: what do you actually do next?

This is where traditional systems break. They’re built on deterministic “if-then” logic. These rules work beautifully when one thing goes wrong, and collapse when three things go wrong simultaneously. Non-linear disruptions don’t queue politely. They compound.

The result? Business owners are drowning in data but starving for decisions.

This is also where Generative AI in transportation and logistics enters, but not as a content generator. Now it will be your semantic reasoning engine. One that bridges fragmented data silos, interprets context, and moves organizations from visibility (knowing where the truck is) to orchestration (knowing what to do because the truck is late).

The adoption curve tells the story. Today, just 28% of supply chain firms actively use AI. By 2029, that number is projected to hit 82% – nearly tripling in four years. Yet despite this momentum, only 9% of companies deploy AI widely across their supply chains. The gap between awareness and implementation remains massive, which means the window for competitive differentiation is still open, but closing fast.

What follows is a practical look at how that shift from visibility to orchestration actually works across the logistics value chain.

Table of Contents

Key Takeaways:

- 3.5x median ROI over three years for AI investments in logistics, but only 9% of companies deploy it widely. The gap between awareness and implementation is where competitive advantage lives.

- 50% reduction in forecasting errors and 65% fewer lost sales when predictive synthesis replaces legacy alert systems.

- 93% of warehouses run WMS; only 10% have intelligent automation. GenAI closes that gap, unlocking 7–15% additional capacity without expanding footprint.

- 5–20% logistics cost reduction for companies embedding AI into operations with D&D mitigation and document reconciliation delivering fastest payback.

- 74% of GenAI initiatives meet or exceed ROI expectations – when built on enterprise-grade architecture with governance guardrails, not generic wrappers.

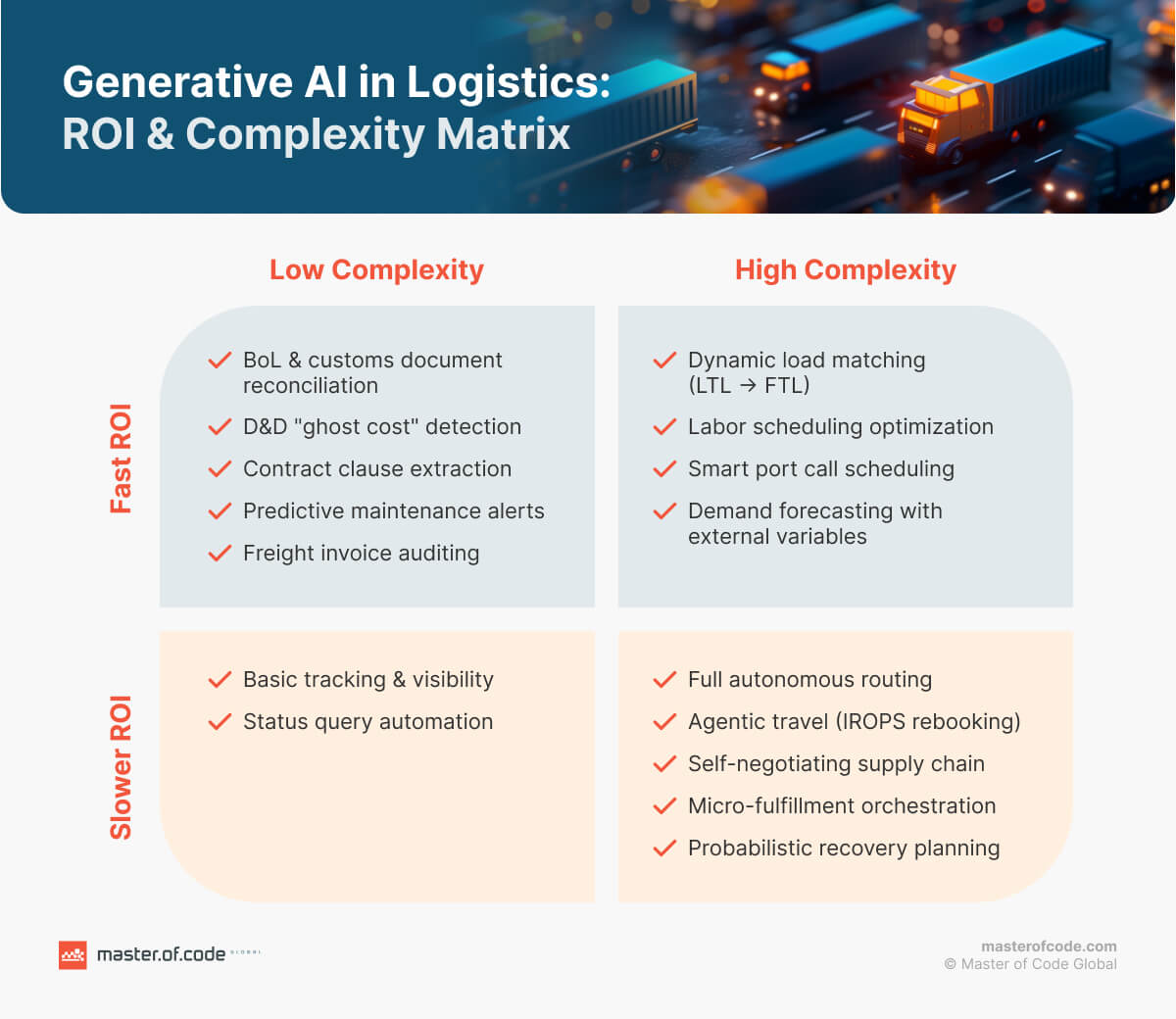

Integrated Use Case Matrix

Generative ai in logistics isn’t a single tool you plug in and forget. It’s a capability layer that transforms each function differently. For example, procurement doesn’t need the same intelligence as port scheduling, and warehouse slotting has nothing in common with travel rebooking.

The numbers back this up. Companies with mature, AI-enabled supply chains achieve 23% higher profitability than their peers – 11.8% margins versus 9.6%. That’s not a rounding error. That’s the difference between market leaders and everyone else. Meanwhile, 55% of large enterprises have already implemented at least two Generative AI use cases, according to McKinsey, signaling that this is no longer experimental territory.

Here’s how technology plays out in the logistics sector.

Supply Chain Management

The traditional model of supply chain planning treats negotiation and forecasting as separate activities – one handled by procurement teams in quarterly reviews, the other buried in spreadsheets nobody fully trusts. Generative AI in transportation and logistics collapses that wall.

The “Self-Negotiating” Supply Chain

AI systems now handle autonomous spot-rate bidding and contract renegotiation based on real-time capacity shifts. Platforms like Pactum, deployed by Maersk and Walmart, demonstrate the model: routine negotiations happen algorithmically, freeing human teams for strategic relationships that require judgment.

Predictive Synthesis

As we have already mentioned, legacy systems tell you something went wrong, but can’t tell you what to do about it.

Predictive synthesis changes the question. Instead of “your shipment is delayed,” this supply chain AI agent generates probabilistic recovery plans, comparing multi-modal alternatives, calculating carbon tax implications, drafting rerouting orders ready for approval. This is disruption management that actually manages.

The impact on demand forecasting accuracy is measurable: GenAI in the supply chain reduces errors by up to 50% and cuts lost sales by up to 65%.

Case Study: Intelligent Demand Planning for a Food Ingredients Distributor

A leading EU distributor of premium baking ingredients faced the classic perishability dilemma: overorder and watch inventory expire, or underorder and miss seasonal spikes.

We built an inventory intelligence engine correlating historical sales with external variables like harvest reports, holiday calendars, supplier lead-time variance. The system simulates scenarios like a poor Madagascar vanilla harvest, recommending procurement adjustments before shortages hit. This is data-driven logistics planning as a living process.

Results:

- 34% decrease in inventory spoilage

- 29% improvement in forecast accuracy

- 35+ hours saved weekly by purchasing team

- 21% reduction in emergency air-freight costs

Fulfillment and Warehousing

The survey by Modern Materials Handling reveals a gap: 93% of warehouses use WMS software, but only 10% have highly automated order fulfillment. Nearly everyone has the system, but almost no one has artificial intelligence in place.

Beyond Barcodes

Traditional warehouse tech reads labels. “Vision + Language” models understand intent: interpreting handwritten notes, identifying misplaced inventory visually, flagging anomalies barcode scanners miss. When a pallet ends up in the wrong zone, the AI traces how it happened and suggests slotting adjustments. This is warehouse operations optimization that learns, not just tracks.

Dynamic Slotting & Labor

Generative AI creates optimal labor schedules accounting for predicted order volume, individual worker certifications (forklift, hazmat, cold chain), and historical surge patterns, so there is no manual input required. When orders spike unexpectedly, real-time operational visibility allows the system to reallocate picking routes on the fly. The result: 7–15% additional warehouse capacity unlocked without expanding the footprint.

Micro-Fulfillment

“Next-hour” delivery in urban markets requires orchestrating inventory pooling across distributed micro-hubs, dynamically shifting stock based on localized demand. AI coordinates what would otherwise be impossible: which hub holds what, which driver picks from where, which order gets priority.

Shipping and Ocean Logistics

Ocean freight moves 90% of global trade, yet the industry still runs on paperwork, phone calls, and penalty clauses that punish inefficiency. Companies embedding AI into their transportation and logistics operations see 5–20% cost reduction, according to McKinsey. Here’s where that value comes from.

Detention & Demurrage Mitigation

D&D fees are the silent margin killer. Carriers bury penalty clauses across thousands of pages of tariffs and contracts – different rules per port, per terminal, per shipping line. No human team can track it all.

LLMs ingest this unstructured logistics data and surface “ghost costs” before the vessel even berths. The AI cross-references your booking against terminal rules, flags conflicts, and calculates the true cost of delays. This is operational cost optimization that happens upstream, not after the invoice arrives.

Smart Port Calls

AI-driven scheduling coordinates with terminal operators to compress vessel idle time, allowing ships to adjust speed en route based on real-time port congestion data. Instead of arriving to wait for an available berth, vessels utilize “just-in-time” arrival logic to minimize fuel burn. The impact is dual-fold: firms leveraging dynamic route optimization and planning achieved 20% fuel cost savings, while broader AI optimization is projected to reduce total freight logistics emissions by up to 15%. This way, companies effectively convert environmental compliance into a measurable operational gain.

Automated Document Reconciliation

Bills of Lading. Commercial Invoices. Packing Lists. Customs declarations. Each generated separately, often by different parties, frequently mismatched.

Generative AI reconciles these documents in seconds, matching line items, flagging discrepancies, catching errors that manual audits miss. The result: fewer customs holds, faster clearance, and decision support systems that surface problems before they become delays.

Travel and Transportation

The gap between customer expectation and operational reality has never been wider. Travelers expect instant resolution. Airlines and transport operators struggle to manage cascading disruptions manually. AI closes that gap not with chatbots, but with autonomous action.

The Shift to Agentic Travel

Forget scripted chatbots that route you to a human after three failed prompts. Agentic AI systems act on your behalf. They don’t just answer “what’s my flight status?” They rebook you when the answer is bad news.

This is the move from reactive support to autonomous concierge: AI that monitors, decides, and executes within defined parameters. The traveler wakes up to a solved problem, not a notification requiring action.

IROPS (Irregular Operations) at Scale

When a flight cancels, the downstream chaos multiplies fast. This includes rebookings, hotel vouchers, loyalty tier considerations, corporate travel policy compliance. Managing this manually during a weather event affecting dozens of flights is nearly impossible.

Generative AI in logistics applied to travel means the system autonomously rebooks passengers based on corporate policy, traveler loyalty status, and real-time hotel availability. No queue. No hold music. The AI handles fleet management workflows across air, ground, and accommodation simultaneously.

The operational payoff extends beyond customer experience. AI tracking delivers 20% improvement in on-time deliveries, according to Forrester. And the same optimization logic applies to moving people, not just packages.

Enterprise-Grade GenAI Solutions

Pilots are easy. Production is hard. In fact, 74% of organizations report their GenAI initiatives meeting or exceeding ROI expectations, but that success isn’t accidental. It comes from treating AI as infrastructure, not a feature. Scaling Generative AI in transportation and logistics across worldwide operations demands architecture most vendors can’t deliver.

Multi-Region Deployment & Low Latency

Global operations don’t pause for cloud latency. When AI runs on a vessel mid-Pacific or in a remote warehouse with spotty connectivity, milliseconds matter. Edge deployment (processing decisions locally rather than round-tripping to centralized servers) becomes non-negotiable.

Production-ready AI systems must function whether the connection is fiber or satellite. That means lightweight models optimized for on-device inference, with graceful fallbacks when connectivity drops.

Governance & Guardrails

Autonomy without boundaries is a liability. Enterprise-grade deployments require policies that define what AI can decide independently and what requires human-in-the-loop decision making.

This includes compliance with international trade laws, customs regulations, sanctions lists, and internal safety protocols. The system must know what it’s not allowed to do—automatically flagging edge cases for human review rather than guessing.

Token Optimization & Cost Management

LLMs are expensive at scale. Every query costs tokens; every token costs money. Generative AI strategic cost management means tiered model architecture: smaller, faster models handle routine tracking and status queries, while larger reasoning models reserve capacity for complex decisions. Without this discipline, compute costs explode. With it, AI becomes sustainable at enterprise scale.

The Decision-Maker’s Roadmap: ROI and Risk

The question isn’t whether Generative AI in transportation and logistics delivers value – that debate is settled. Median ROI for these investments in the sector hits 3.5x over three years. The real question is how to capture that value without burning your budget on pilots that never scale.

From Pilot to Production

Not all use cases deserve equal investment. Start with “high-gravity” data points, areas where AI delivers fast, measurable ROI with minimal integration complexity.

Document automation typically wins this race. Bills of Lading reconciliation, customs invoice matching, contract clause extraction – these processes are high-volume, error-prone, and rule-bound. Perfect AI territory. Full autonomous routing, by contrast, touches more systems, requires more trust, and takes longer to prove. Start where the wins are fast and expand where the value compounds.

Being a trusted Gen AI development company, Master of Code Global understands the nuances of the field and will guide you toward these high-gravity starting points rather than selling the moonshot first. That’s why we offer a fixed-price Proof of Concept – a contained engagement that proves value on your data, in your environment, before broader commitment. No six-month discovery phase. No runaway scope.

KPI Shift

Legacy metrics obscure AI’s true value. “Cost per Mile” tells you efficiency in isolation. It doesn’t capture resilience.

Better measures:

- Time to Resolution: how fast you recover from disruption.

- Network Resiliency: how well your operations absorb shocks without cascading failures.

These metrics reflect what AI actually improves: not just steady-state efficiency, but adaptive capacity when things go wrong.

Predictive and prescriptive AI delivers 10–20% reduction in operations costs. But the deeper value is avoiding the costs you never see: the expedited shipments that didn’t happen, the penalties that didn’t hit, the customers that didn’t churn.

The Human Element

The goal isn’t replacing dispatchers. It’s building them Iron Man suits.

Gen AI consulting services should focus on enhancing decision-making capacity – surfacing options, quantifying trade-offs, drafting actions – while keeping humans in command of judgment calls. The AI handles volume and speed; people handle nuance and relationships.

This is where the 74% success rate comes from. Not from automation alone, but from augmentation done right.

The Bottom Line

Generative AI in transportation and logistics isn’t coming. It’s here, and the gap between early movers and everyone else is widening fast. The window for competitive differentiation is still open, but closing. The question isn’t if, but how fast you move.

At Master of Code Global, we don’t build dashboards. We develop the nervous system of your operations – proprietary, governed, scalable.

Ready to see what AI can do with your data? Book a session with our experts and walk away with a clear roadmap, not a sales pitch.