If you’ve been following the latest tech news, you might know about the significant progress in Artificial Intelligence. One big breakthrough is the rise of Generative AI models. And it seems that Gen AI trends could change the way we manage things, learn, and communicate.

Day by day, new technologies are transforming the way businesses operate and manage their supply chains. These emerging solutions offer promising advantages like optimization, cost and time savings.

Supply chain management is an integral part of any business. It controls the flow of goods and services from the manufacturer to the end consumer. In this article, we will delve into some of the ways that companies can use Generative AI in supply chain operations. Let’s investigate the potential of Generative AI to go beyond routine processes.

Table of Contents

Generative AI in Supply Chain Today

In a world where supply chains are getting more complex, there’s a growing need for new digital solutions. Many companies are finding that their supply chain isn’t working in an environment with constant disruptions, limits, and shortages. Generative AI for supply chain management can give them better visibility and insights. This way, they can address disruptions before they happen.

Improve your Generative AI knowledge with 65 use cases for effective industry applications.

A recent McKinsey survey found that about one-third of companies are now using Gen AI across at least one business function.

The study shows the sectors where Gen AI can promptly be embraced:

- customer service (78%)

- operations process optimization (66%)

- production planning and scheduling (47%)

- quality control and inspection (44%)

- inventory management (43%)

According to another study, by 2026, more than half of the world’s largest manufacturers will use artificial intelligence to redesign their service supply chains. This will guarantee that the right spare parts are available where they are needed and will help to solve three-quarters of all problems before they cause a failure. By 2028, the use of robotics and automation in warehouses will have increased tenfold, resulting in a 30% increase in productivity.

Supply chain planning solutions leader, OMP, showcases notable Generative AI examples. One more remarkable illustration shows Microsoft. In 2021, the company announced Microsoft Dynamics 365 Copilot. These AI tools may impact supply chains by collecting supplier-related news, such as information on natural disasters and geopolitical situations. These instances demonstrate the various applications of AI in diverse industries.

The Gen AI market in supply chain management is seeing rapid economic growth. From 2023 to 2032, the market is expected to grow at a CAGR of about 45.62%, reaching around USD 12,941.14 million by 2032 from USD 301.83 million in 2022. This growth is indicative of confidence in Gen AI’s potential to enhance supply chain operations.

These statistics underscore how Generative AI can drive supply chain transformation. We see the rapid adoption of these technologies in business operations. Which reflects economic growth expected in the market over the next decade.

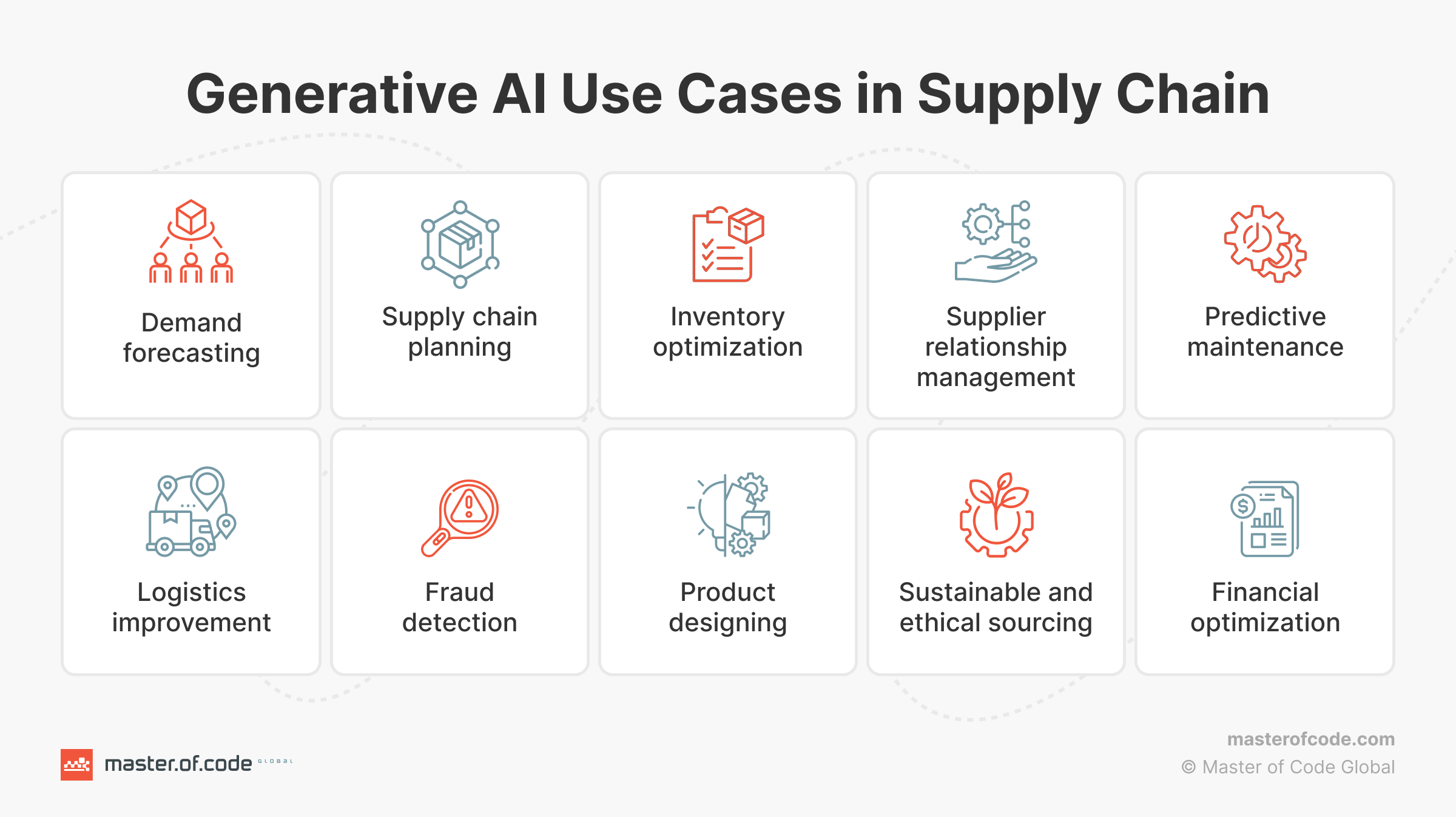

Generative AI applies to various use cases, like predicting maintenance and optimizing inventory or product design. Such software automates important tasks, enhancing efficiency and productivity in the industry. Now we will delve more into use cases and real examples.

Generative AI Use Cases in Supply Chain

Did you know that 72% of companies plan to increase their investments in integrating Generative AI into business? Deployment of this innovative technology presents numerous advantages for companies. In this section, we will dive deep into Generative AI use cases in the supply chain sector.

Demand Forecasting

Generative AI has the capability to model various situations and generate analyses. This lets businesses explore diverse demand scenarios, assess the impact of different factors, and enhance decision-making with more insights.

Predicting demand is essential for supply chain management. It helps businesses optimize inventory, and reduce the risk of stockouts.

Generative AI uses historical data, market trends, and external factors to create more accurate demand forecasts. By considering different factors at once, these models can identify complex patterns that traditional forecasting methods might miss.

This ability allows businesses to expect changes in demand and adjust production and inventory levels accordingly. Summing up, companies will improve operational efficiency and cut down costs.

As we have already mentioned above, Microsoft released Dynamics 365 Copilot, which offers AI-powered help for various business tasks, including supply chain. New capabilities for Microsoft Supply Chain Center are now available to Dynamics 365 Supply Chain Management customers. Let’s explore some of its key features:

- Stay ahead of disruptions: Predict and act on potential disruptions across suppliers, weather, or geography.

- Identify external risks: Use news module intelligence to identify external issues that could affect your supply chain processes.

- Gain proactive insights: Predict how disruptions might impact your orders, materials, inventory, carriers, distribution networks, etc.

Copilot uses Azure OpenAI Service to create personalized emails for supply chain managers. These emails help them deal with disruptions and fulfill customer orders efficiently.

Here are some results of the impact of Supply Chain Management:

- Achieved a 90% ROI using Dynamics 365 Supply Chain Management in three years;

- Enhanced operational efficiency by $1.5M through reduced unplanned machine downtime;

- Seen a potential 50% increase in developer productivity.

Supply Chain Planning

Planning, powered by AI tools, brings substantial benefits to companies. Factoring production capacity, lead times, and demand, software streamlines planning. This process ensures a smooth and uninterrupted flow of goods from manufacturers to end consumers.

These operations’ optimization can minimize bottlenecks, reduce delays, and enhance overall productivity. Besides, such an approach fosters customer satisfaction and loyalty. With streamlined supply chain planning, you can reduce costs, and gain a competitive edge in the market.

OMP, a leader in supply chain planning solutions, collaborates with Fortune 500 customers to launch Generative AI pilots. The company has been delivering groundbreaking AI solutions to customers for many years. The main aim is to elevate digital supply chain planning to a new level of interactivity and intelligence.

This way, customers can receive practical assistance when reviewing documentation. Furthermore, it will enhance access to expert knowledge for both new and experienced users.

Gen AI will let the OMP platform provide helpful information when users ask questions in their own words. For instance, it can explain the reasons behind a suggested plan and show the effects of changes by creating charts and graphs.

Generative AI in the supply chain is making information accessible to a wider range of people within an enterprise. Looking ahead, businesses can make better decisions and improve their overall performance.

As an experienced Generative AI service company, we provide innovative solutions customized for your business. The Master of Code Global team is dedicated to assisting your business in developing and integrating proven use cases. This strategy will take your competitive advantage to the next level!

Inventory Optimization

Businesses need to avoid stockouts, but they also have to minimize the cost of storing too much goods. Generative AI can help fine-tune inventory management. By forecasting ideal stock levels based on demand trends and external factors.

This can help businesses cut down excess holdings, avoid overstocking, and make their supply chains more agile. This technology aids in identifying the most efficient distribution management methods, taking into account lead times, transportation costs, and changes in demand.

Domino’s Pizza UK & Ireland uses AI to meet client desires and deliver a better future for its customers and employees. To ensure great customer experiences and timely product delivery, Domino’s used spreadsheets to predict demand. They have now automated this process using AI and analytics in Dynamics 365, improving their forecasting quality.

Supplier Relationship Management

Generative AI in supply chains is increasingly becoming a mainstream solution. By analyzing suppliers and markets, Gen AI identifies reliable partners. This process fosters stronger relationships, ensuring a consistent and high-quality flow of goods or services.

By cultivating these relationships, you can negotiate better terms, access competitive pricing, and secure favorable contract terms. Thereby, it reduces procurement costs and raises overall supply chain efficiency.

Moreover, it reduces risks, ensuring continuous operations. With a more efficient and reliable supply chain, your business can drive profitability. It can also enhance customer satisfaction and position itself as an industry leader in its respective market.

Predictive Maintenance

The use of Generative AI in the supply chain is significantly influencing the industry. Yet, many unexplored opportunities show large potential for further advancement.

Predictive maintenance, facilitated by Generative AI models, provides substantial advantages. By leveraging data from machines on the factory floor, such tools predict when equipment is likely to fail.

Furthermore, this enables manufacturers to optimize maintenance schedules. Resulting in minimizing downtime and costs, while also extending the lifespan of their equipment. With this proactive approach, businesses can raise operational efficiency, improve productivity, and reduce overall maintenance expenses.

AI-Powered Parts Bot for Aviation: Optimizing Aircraft Maintenance

Master of Code Global created an AI-powered parts sourcing chatbot for airlines to optimize their aircraft maintenance operations. This solution automates tasks like checking part availability, tracking orders, and managing customer inquiries, significantly reducing manual effort and speeding up response times.

Similar to predictive maintenance models in manufacturing, this chatbot helps airlines proactively address operational issues by streamlining the process of sourcing critical components, ensuring minimal downtime and more efficient workflows. By integrating multiple communication channels such as web, voice, and SMS, the bot provides a scalable solution that enhances both customer service and operational efficiency, much like how predictive maintenance improves machine uptime in supply chain management.

Logistics Improvement

Supply chain management is the anchor of any product business. It handles the complicated steps of procurement, production, distribution, and logistics.

If you’ve ever considered minimizing delivery times and costs, the solution is obvious: Generative AI for manufacturing. Adoption of such models excels at optimizing transportation routes.

All these improvements affect factors like vehicle capacity, traffic conditions, and fuel consumption. All these lead to improved supply chain efficiency. And it seems that with streamlined logistics, businesses can improve customer satisfaction, and reduce operational expenses.

Fraud Detection

According to the statistics, 75% of companies in retail plan to use AI to fight fraud. Furthermore, Generative AI in retail harnesses its first benefits. One of the advantages of AI applications is that they can be fine-tuned. You can train these models to forecast the probability of fraud occurrences. By analyzing financial data, Gen AI can identify intricate patterns. This is how such tools aid in the detection of fraudulent activities.

The use of Generative Adversarial Networks (GANs) involves a generator network creating synthetic fraudulent transactions and a discriminator network identifying them. This combined system significantly improves fraud detection accuracy. Moreover, it will aid not only in identifying and preventing law-breaking, but also in strengthening the security of the supply chain.

This holistic approach not only safeguards businesses against potential financial losses but also enhances security. It instills trust among stakeholders and fosters a more reliable supply chain management system.

Product Designing

Generative AI in the supply chain accelerates the innovation process significantly. This cutting-edge technology generates and assesses many alternative designs according to specific criteria.

For instance, companies can use Generative AI chatbots for diverse design purposes. These bots can aid in the development of new machinery parts. They can facilitate the creation of products that are more efficient, durable, or visually appealing.

Such a streamlined approach not only expedites the design process but also enhances product quality. You’ll get a higher customer satisfaction rate, and gain market competitiveness. Summing up, the technology will increase business success and growth.

Sustainable and Ethical Sourcing

This technology effectively tracks product origins and monitors supplier practices. It assists businesses in guaranteeing sustainable and ethical sourcing. This meets regulatory compliance and fulfills the demand for eco-friendly products.

Let’s take, for example, an application that analyzes carbon emissions, transportation modes, and material sourcing. With such eco-friendly assistants, companies can remain committed to social responsibilities. Still, they can also meet their business goals and develop environmentally friendly supply chains.

In this way, your brand can enhance its reputation and customer loyalty. Moreover, Generative AI in supply can help reduce the environmental footprint, making a positive impact on the planet.

Financial Optimization

This strategic use case shows how businesses can optimize their budget allocation and minimize unnecessary expenses. Such technology uses advanced algorithms to help allocate financial resources effectively. It enables businesses to make data-driven decisions, enhance cost-efficiency, and maximize overall profitability.

The software identifies potential areas for cost reduction by performing financial analysis and predictive modeling. It also streamlines operations and ensures a sustainable and robust financial framework. This method empowers businesses to navigate market fluctuations with resilience and agility.

Master of Code Global – Your Partner in Technological Advancements

Generative AI is becoming an essential tool in modern supply chain management. More and more businesses achieve greater agility, resilience, and competitiveness in a rapidly changing market environment. As technology continues to evolve, its role in supply chain transformation will undoubtedly grow. Its progress offers even more innovative ways to address traditional and emerging challenges.

The transformative potential of Generative AI within the chain sector is huge and multifaceted. It helps businesses optimize inventory, forecast demand more, and improve logistics. It equips them with the agility to respond to market dynamics and the efficiency to reduce operational costs.

Master of Code Global stands at the forefront of this technological revolution. With a successful history in AI solution development, our company has a strong grasp of supply chain management complexities. We will develop and deploy the best-fitting customized solutions for your business.

Our skilled team uses expertise to turn your data into useful information. This will save you money, making the supply chain more efficient. All these methods will give you a better understanding of your business.

If you want to improve your demand forecasting, supplier relationships, or product design, contact Master of Code Global. We can give you a hand with adopting Generative AI in the supply chain to make your business smarter and more efficient. Let’s create exceptional products together!

Don’t miss out on the opportunity to see how Generative AI can boost your company’s efficiency.