Ever feel like you’re one disruption away from a supply chain meltdown? What if you could anticipate and mitigate risks before they even happen? In today’s turbulent business environment, logistics leaders are facing a waterfall of challenges. It’s a complex web of interconnected players, volatile demand, and unforeseen disruptions lurking around every corner. Like conducting an orchestra in the middle of a hurricane, you’re constantly battling to maintain harmony amidst the chaos. How can Agentic AI in the supply chain navigate these challenges? We will show you!

Interestingly, while over half of industry leaders identify better visibility as their top priority, this trend seems to be shifting. Smaller organizations are increasingly focusing on agility and responsiveness, recognizing that visibility alone isn’t enough to weather the storm. But what if there was a way to achieve both? What if you could not only see the disruptions coming but also empower your organization to react intelligently and autonomously?

In this article, we’ll explore the groundbreaking potential of AI agents for supply chain management. But we won’t just tell you about it – we’ll let you experience it. Through a series of interactive scenarios, you’ll discover how these assistants empower companies to make smarter decisions, overcome challenges, and ultimately, orchestrate a logistics model that thrives even in the face of uncertainty. Get ready to choose your own adventure for each scenario!

Table of Contents

Your First Choice: A Supply Chain Crossroads

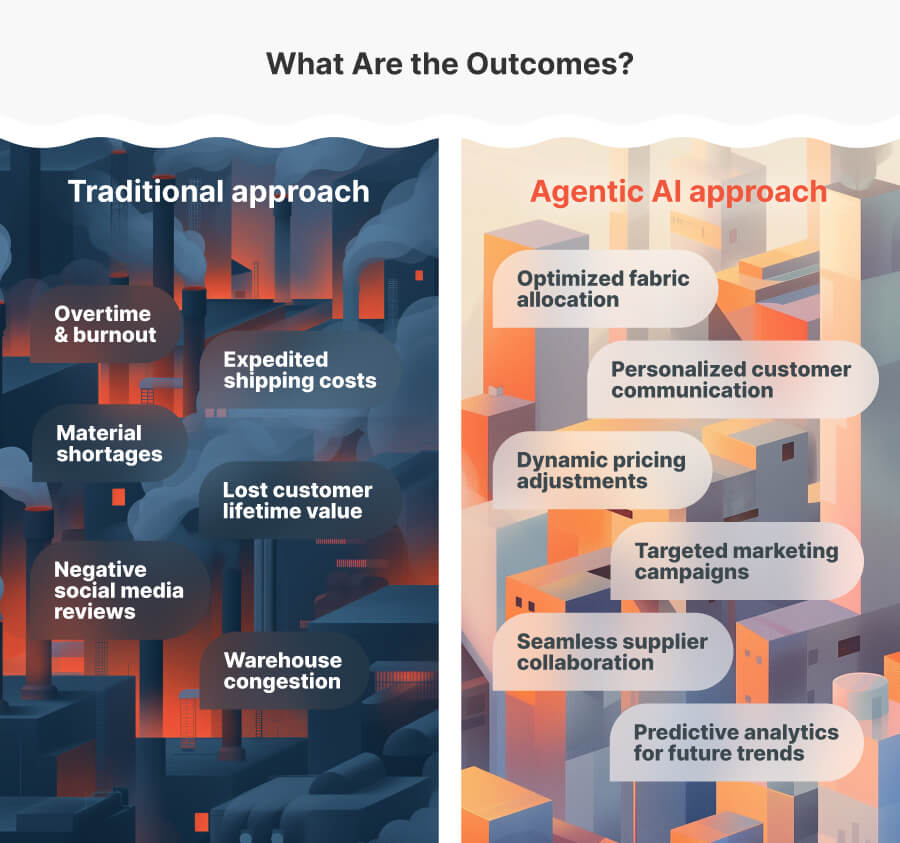

Scenario 1: The Demand Surge. You’re the Head of Supply Chain for a popular athletic wear company. Your latest line of athleisure wear is flying off the shelves. Social media is buzzing, influencers are raving, and orders are pouring in faster than you can keep up. It’s a dream scenario, right? Not necessarily. A sudden, unexpected spike in demand can quickly turn into a logistical nightmare.

Choice A: The Traditional Approach

Your instinct might be to do what many businesses still do – scramble to adjust your production plans manually. You pull out your trusty spreadsheets (after all, McKinsey reports that almost 73% of businesses in this sector still rely on these traditional tools), gather your team, and start crunching the numbers.

But as you dive into the complex web of spreadsheets, you realize the limitations. Can you accurately forecast the demand surge? Do you have enough raw materials? Can your manufacturing partners ramp up production quickly enough? And how will you communicate potential delays to your eager customers?

Choice B: The Agentic AI Solution

Now, imagine a different scenario. Instead of manual chaos, you have an AI agent for logistics at your disposal. This intelligent system constantly monitors your supply chain AI consulting, analyzing data from various sources – sales figures, social media trends, even weather patterns. It detects the consumption boom in real-time and springs into action.

- Demand Forecasting: The AI agent doesn’t just look at past sales data; it analyzes real-time signals like social buzz and online searches to predict the spike in orders.

- Production Planning: It automatically adjusts factory schedules, optimizing your manufacturing capacity to meet the increased number of requests.

- Supply Network Optimization: Your intelligent solution assesses your raw material needs and identifies alternative providers if your current partners can’t keep up.

- Store Replenishment: For retailers, the AI agent goes a step further. It automatically generates refilling orders for your shops, ensuring shelves are stocked with the right items at the right time. It considers factors like sales velocity, upcoming promotions, and even local events to optimize inventory levels and prevent stockouts.

- Inventory Management: It ensures you have enough space on hand to meet the surge, while minimizing excess stock and storage costs.

Deeper Dive: How Agentic AI Works

Before we reveal the consequences of your choice in the demand surge scenario, let’s take a quick detour to understand the engine behind the Agentic AI in the supply chain.

This is more than just a sophisticated algorithm; it’s a proactive and autonomous partner in managing your core processes. Think of it as an intelligent helper that constantly monitors your operations, analyzes data from every corner of your network, and takes action to optimize performance and mitigate risks. The same logic applies beyond logistics too — for example, an AI agent for insurance can proactively manage claims workflows, flag fraud signals, and automate customer updates within strict governance rules. It’s the difference between having a weather forecast and having a system that automatically adjusts your thermostat before the temperature even changes.

The Three Pillars of Agentic AI

- Proactiveness: It doesn’t wait for problems to arise, anticipating them. By analyzing historical data, real-time signals, and even predictive models, the software identifies potential disruptions before they impact your operations.

- Autonomy: Within predefined parameters, GenAI for supply chain can make decisions and take action without human intervention. This frees up your team to focus on strategic initiatives, while the algorithms handle the day-to-day optimization and risk mitigation.

- Continuous Learning: An enterprise AI agent solution is not a static system; it learns and adapts over time. By analyzing the outcomes of its actions, the tool continuously refines its models and improves performance.

Agentic AI is rapidly gaining traction. McKinsey’s recent research reveals a growing wave of adoption. And there is no surprise! Already, 20% of executives report implementing AI and machine learning in their logistics planning activities, with a significant 60% planning to do so in the near future. Applications like demand prediction, sales and operations management, and control tower functionalities are leading the charge, demonstrating the tangible value AI brings to the table.

Your Second Choice: The Disruption Dilemma

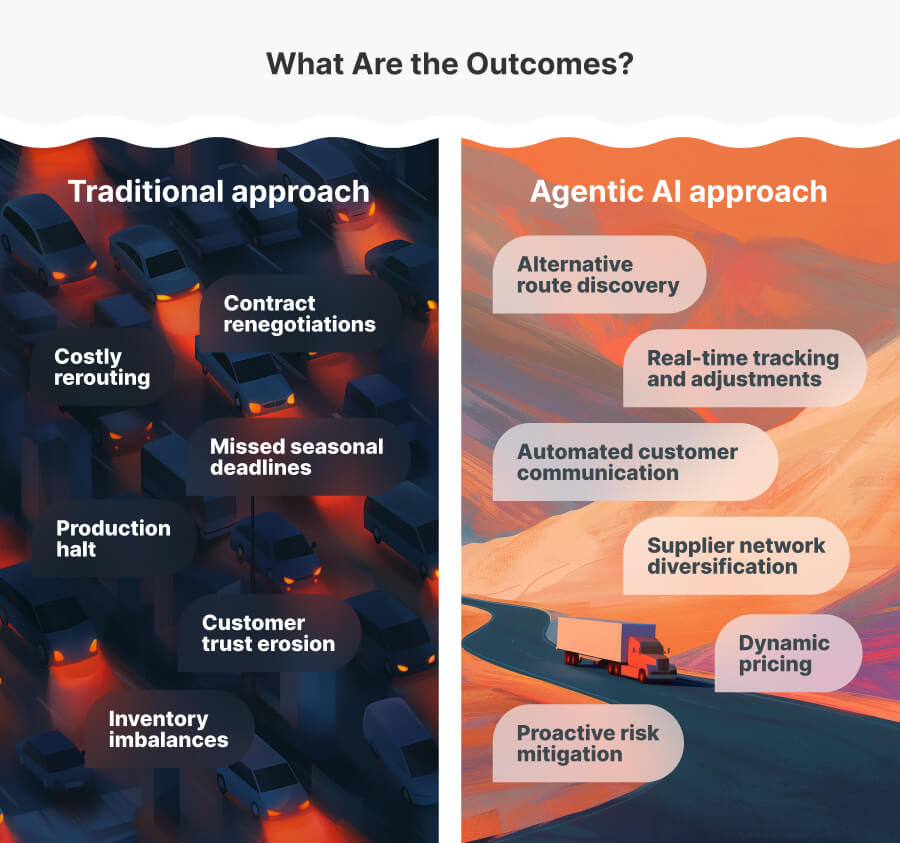

Scenario 2: The Suez Canal 2.0. You’ve navigated the demand surge, but just as you breathe a sigh of relief, another challenge emerges. News breaks of a major shipping route blockage – a “Suez Canal 2.0” – disrupting global trade and throwing your meticulously planned supply chain into disarray. A critical shipment of components for your flagship product is stranded, and your consumers are starting to get anxious.

This scenario highlights the tightrope businesses walk today. Clients demand both speed and affordability, with 38% of companies citing customer expectations as a major concern, while half prioritize low-cost shipping options. The pressure is on to deliver quickly and flawlessly, as 61% of shoppers expect their orders to arrive promptly and in perfect condition. To add to the complexity, 77% of brands now offer free delivery to maintain acceptable buyer satisfaction rates. In this high-stakes environment, any disruption can have a cascading effect on your bottom line and your brand reputation.

Choice A: React and Scramble

Faced with this unexpected crisis, your team goes into overdrive. You frantically search for alternative shipping routes, contact freight forwarders, and negotiate new contracts, all while trying to keep costs under control. Meanwhile, your customer service team is inundated with inquiries about delivery delays, struggling to provide accurate information and manage expectations. It’s a reactive scramble, with no guarantee of success.

Choice B: Agentic AI to the Rescue

But what if you had a secret weapon in your arsenal? Enter your AI agent for logistics, ever vigilant and ready to act.

- Route Optimization: Your software instantly analyzes the situation, identifying alternative delivery routes and transportation modes. It considers factors like cost, transit time, and carrier reliability to find the optimal solution.

- Supplier Management: If necessary, the agent can even tap into its network to identify alternative suppliers or source components from different locations, minimizing the impact of the disruption.

- Proactive Communication: Perhaps most importantly, the solution stays in touch with your customers, comforting them and reducing the level of stress. It provides real-time updates on the situation, informs buyers of potential delays, and even offers alternative options or product substitutions, keeping people informed and satisfied.

AI-Powered Parts Bot for Aviation: Your AI Assistant for Aircraft Maintenance

Imagine an AI assistant that takes over the sourcing of critical aircraft parts, anticipating needs, tracking orders, and managing inquiries all on its own. That’s exactly what Master of Code Global has achieved with its AI-powered parts chatbot, designed to help airlines keep their operations running smoothly, even during disruptions.

Much like the AI agent in the disruption scenario, this bot autonomously tracks and processes parts sourcing for airlines, ensuring that maintenance teams always have what they need, when they need it. Whether it’s checking part availability, ordering supplies, or managing communication across web, voice, and SMS, this solution operates seamlessly—no scrambling needed.

In essence, it’s your agentic AI for aircraft maintenance, empowering airlines to keep their planes in the air without the bottlenecks of manual tracking or human error.

AI Forecasting Engine for Food Distributors

What if your inventory system could think ahead—spotting seasonal trends, reacting to global harvest data, and flagging potential shortages before they happen? That’s the kind of intelligence Master of Code Global brought to life for a major food ingredients distributor. By integrating machine learning with internal ERP data and external market signals, we built a forecasting engine that doesn’t just report the past—it actively guides future buying decisions. The impact? Less waste, tighter planning, and over 35 hours saved every week for the purchasing team.

Your Third Choice: The Sustainability Challenge

Scenario 3: The Carbon Footprint Conundrum. Consumers, investors, and regulators are all demanding greater environmental responsibility, and your supply chain is under scrutiny. Every mile traveled, every warehouse powered, every product manufactured leaves a carbon footprint. The pressure is on to minimize your impact and embrace sustainable practices.

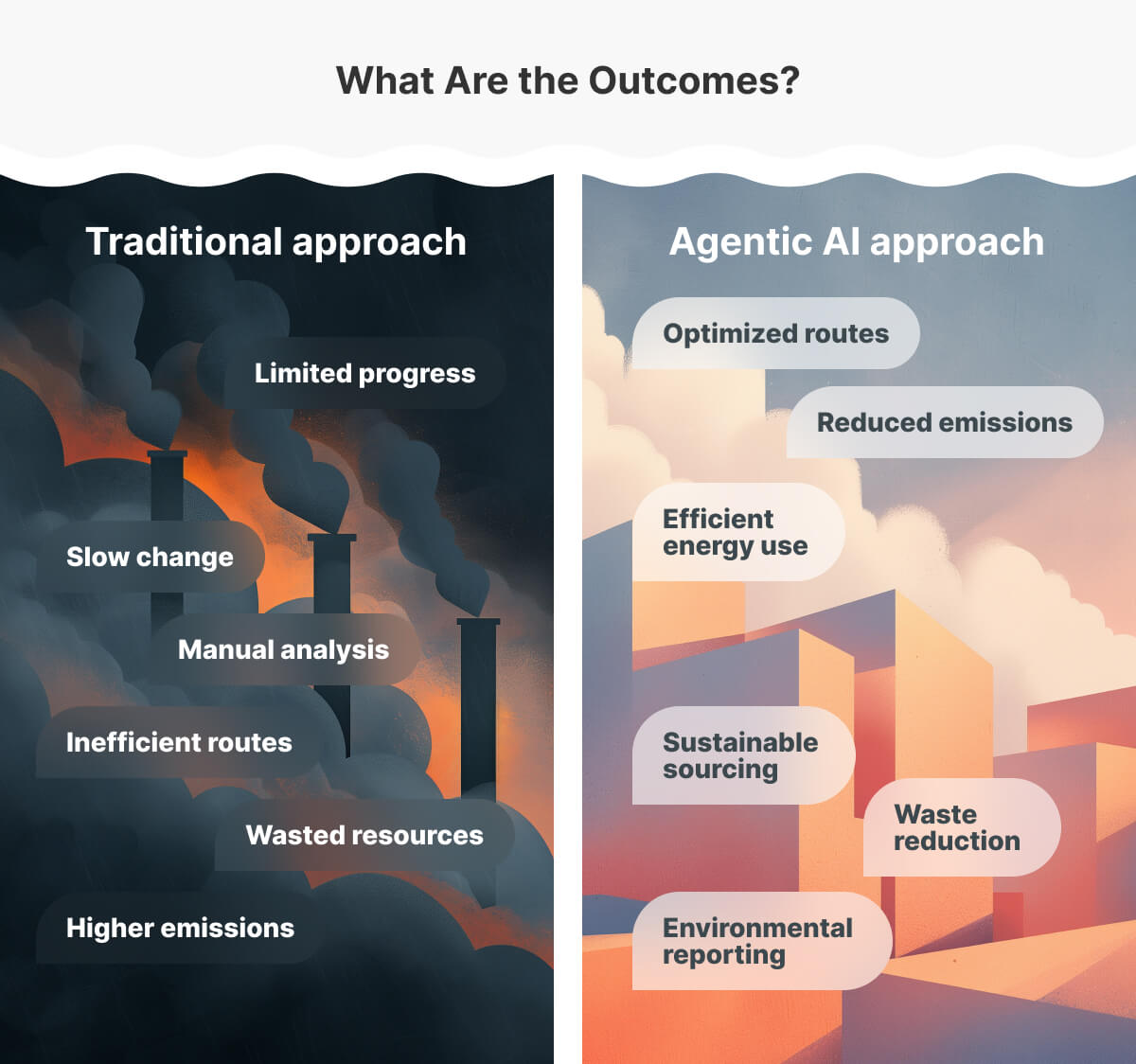

Choice A: Incremental Improvements

You recognize the importance of sustainability and embark on a manual analysis of current operations. You identify areas for improvement – optimizing delivery routes, reducing packaging waste, sourcing from local suppliers. You implement changes, track your progress, and report your achievements. But the process is slow, and the impact feels limited. You’re making progress, but is it enough to meet the growing expectations and stay ahead of the curve?

Choice B: Agentic AI in Action

Imagine a different approach. Your software, with its ability to analyze vast amounts of data and identify hidden patterns, becomes your sustainability partner. It goes beyond surface-level improvements and dives deep into your processes from manufacturing to logistics, uncovering opportunities you might never have noticed.

- Fuel Efficiency Maximization: The AI agent optimizes delivery routes, minimizing mileage and fuel consumption. It considers factors like traffic patterns, vehicle capacity, and delivery windows to ensure efficient and sustainable transportation.

- Fleet Management: The software also analyzes your fleet’s performance, identifying opportunities to reduce resource consumption and emissions. It can even recommend the adoption of electric vehicles or alternative fuels.

- Predictive Maintenance: By forecasting equipment failures before they occur, the AI system helps you minimize downtime and decrease energy waste.

- Supply Sourcing: Agentic AI assesses the environmental impact of your vendors, helping you choose partners who really align with your sustainability goals.

- Traceability: The intelligent solution provides end-to-end visibility into your supply chain, allowing you to track the ecological consequences of every stage, from raw material sourcing to product delivery.

This comprehensive approach delivers tangible results. Studies show that AI-enabled supply chains are 67% more effective than their non-AI counterparts, achieving significant risk reduction and lower costs. By optimizing operations and minimizing waste, agents not only reduce your environmental impact but also improve your bottom line.

Final Thoughts

As you’ve journeyed through these three scenarios, you’ve experienced firsthand the value of Agentic AI. Nevertheless, its applications are unlimited and there could be hundreds of other imagined situations. It’s not just about optimizing your supply chain; it’s about empowering it to thrive in the face of uncertainty. With Agentic AI as your partner, you can navigate demand surges, disruptions, and sustainability challenges with confidence and agility.

Turning these scenarios into real, production-ready systems requires more than experimentation — it demands deep experience in agentic AI consulting services, from architecture design and orchestration to safe autonomy and enterprise-scale integration across complex supply chain environments.

At Master of Code Global, we’re not just an AI agent development company; we’re pioneers in this field. With years of experience and a deep understanding of AI’s potential, we’re passionate about building intelligent agents that solve real-world problems.

Our approach is rooted in collaboration and customization. We work closely with you to understand your specific needs and challenges. After that, the team of skilled engineers develops tailored AI solutions that may be seamlessly integrated with your existing systems and processes. And our commitment doesn’t end with deployment; Master of Code Global provides ongoing support and guidance to ensure your success.

Ready to make the right choices for your company’s future? Contact us today to schedule a consultation and discover how we can help you build a more resilient, responsive, and sustainable supply chain.

Ready to build your own Conversational AI solution? Let’s chat!