Energy companies aren’t typically first movers when it comes to new technology. But that’s changing fast. Our sales and delivery teams have seen a clear uptick in serious artificial intelligence inquiries over the past year. Enterprises are launching:

- Real-time transport safety monitoring;

- Virtual advisors handling bulk orders;

- Call analysis tools;

- Email assistants to prioritize customer communications.

The interest is definitely there, but so is the hesitation. Uncertainty about ROI, limited proven case studies, and the consequences of failure in implementing Generative AI in oil and gas industry create justified caution. When downtime costs $200,000–$650,000 per hour and safety incidents can shut down entire facilities, every technology decision carries weight.

To help ease that weight, we brought together our experience and the projects we’ve delivered. In this article, you’ll see why custom AI for oil and gas deserves a place on your 3–5 year strategic roadmap and 18 practical tips to make the journey smoother.

Table of Contents

Is the Oil and Gas Industry Actually Using Generative AI?

Yes, and the numbers demonstrate rapid expansion. This market is valued at $4.0 billion and is estimated to reach $14.9 billion by 2035, with a compound annual growth rate of 14.1%. Businesses are putting real money into GenAI because the costs of not doing so are too high.

Consider unplanned downtime. When a drill stops working or a pipeline develops issues, organizations lose between $200,000 and $650,000 per hour, depending on oil prices. In 2022, when it hit nearly $120 per barrel, a single hour of lost production cost over $600,000. These losses explain why predictive analytics has become a priority.

Maintenance itself eats up 15–70% of total production expenses, making it the second-largest expense after energy. Traditional approaches rely on scheduled inspections and reactive repairs. Generative AI in oil and gas industry changes this by analyzing sensor data, equipment logs, and historical patterns to predict failures before they happen.

Current implementation varies across the value chain. Today, 44% of exploration operations use this technology, while production sits at 40%. Transportation and storage lag at 28%. However, projections for the next three years show exploration reaching 89% adoption, drilling 85%, and production 90%. Even retail and marketing will jump from 31% to 66%.

The gap between current and projected usage shows that most companies recognize the need to implement artificial intelligence. The question becomes which applications deliver returns fast enough to justify the investment.

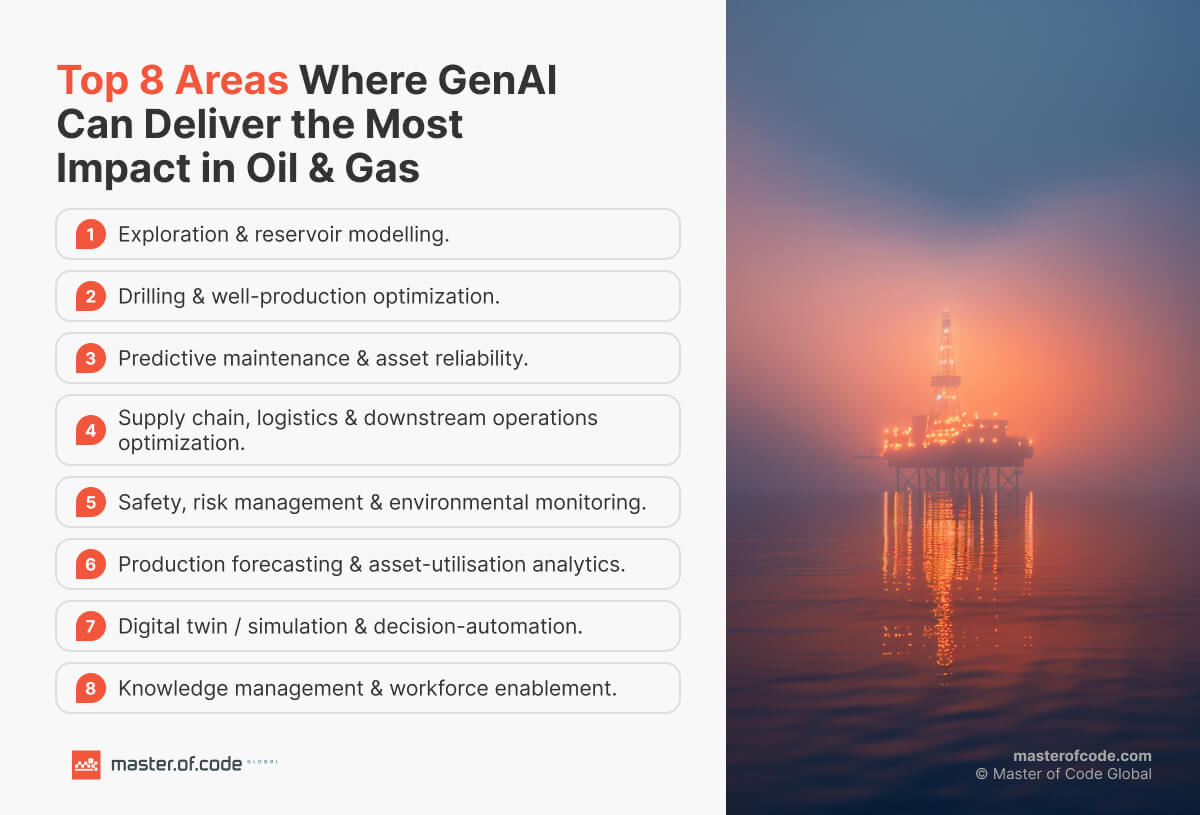

Which Generative AI Use Cases in Oil and Gas Industry Show the Quickest Returns?

Not all solutions are created equal when it comes to ROI. The difference is in how directly each addresses high-cost operational problems and how quickly it can be implemented without overhauling existing systems.

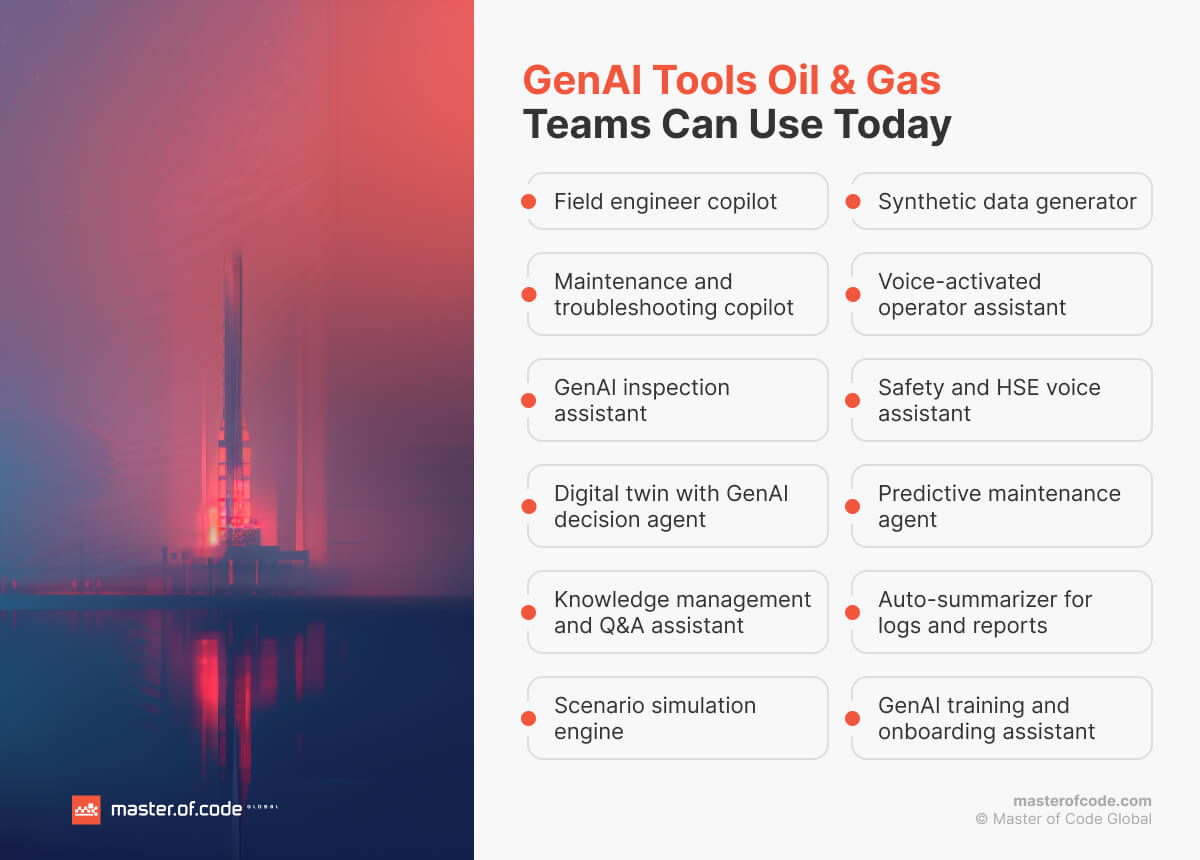

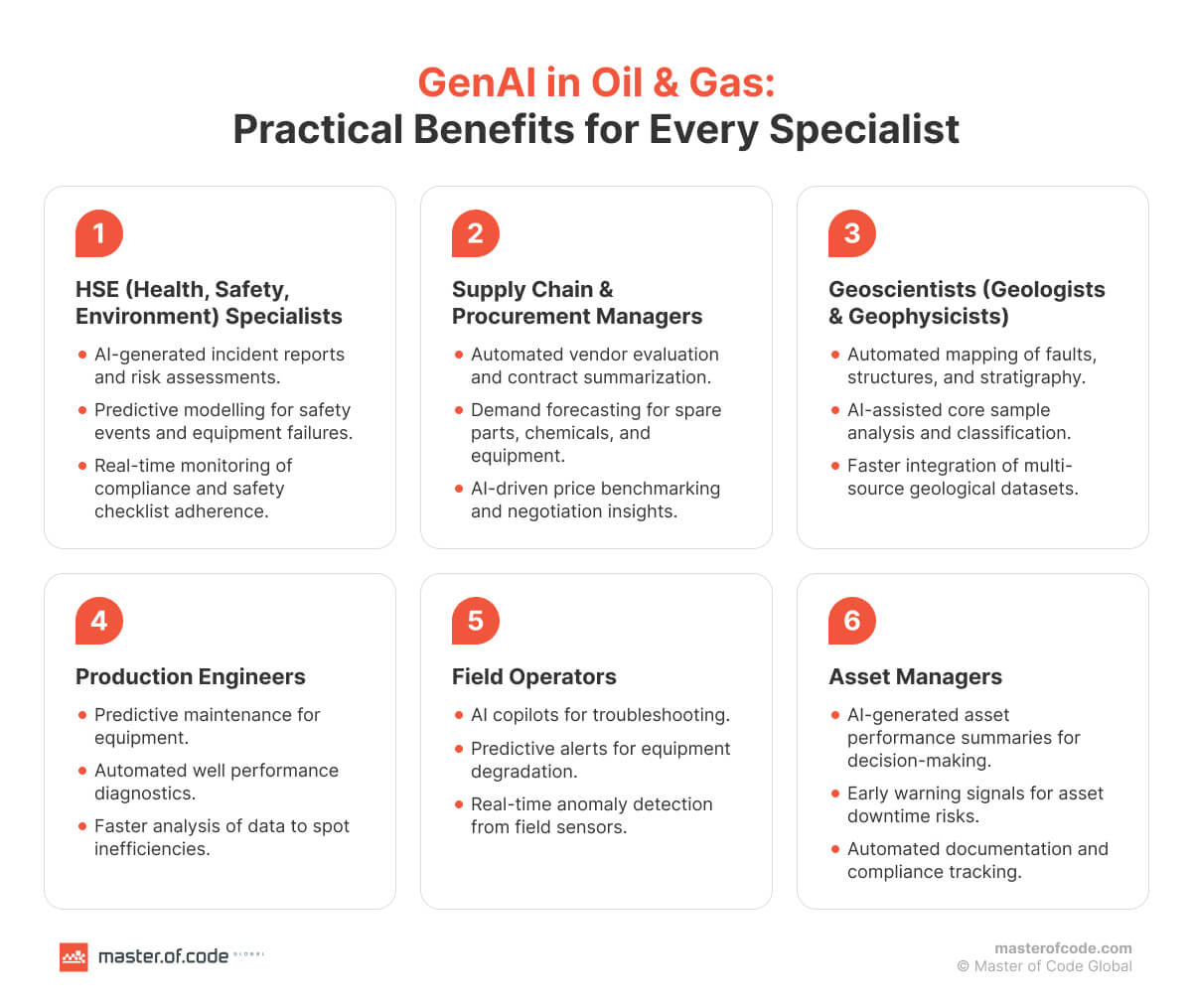

Here are the AI use cases in oil and gas that may offer the fastest payback periods.

Predictive Maintenance & Equipment Health Monitoring

GenAI analyzes real-time sensor data, logs, and machinery performance history to predict malfunctions before they occur. Instead of fixing broken pumps or replacing corroded valves after downtime happens, operators receive alerts days or weeks in advance.

This approach delivers:

- Prevention of catastrophic failures that lead to expensive emergency repairs;

- Reduction in unplanned downtime through early intervention;

- Extended equipment lifespan by addressing issues before they cause cascading damage.

Supply-Chain Optimization

Managing spare parts inventory across remote drilling sites, offshore platforms, and refineries creates constant headaches. AI models predict which components will fail, when they’ll fail, and where they’re needed. The system then optimizes procurement timing and distribution routes.

Key improvements include:

- Lower inventory carrying costs by stocking only what’s necessary;

- Faster response times when critical parts are required at remote locations;

- Better demand forecasting that accounts for seasonal patterns and tools age.

Enhanced Safety Monitoring & Anomaly Detection

Advanced algorithms monitor video feeds, sensor networks, and operational data to spot hazards in real time. The technology identifies gas leaks, equipment overheating, unauthorized personnel in restricted zones, and deviations from standard operating procedures.

Results operators see:

- Immediate alerts when dangerous conditions develop;

- Fewer false alarms compared to traditional threshold-based systems;

- Pattern recognition that catches risks human observers might miss during long shifts.

Energy-Consumption & Efficiency Optimization

Energy costs represent the largest operational expense in oil and gas. Generative AI in oil and gas industry analyzes power usage patterns across facilities, determines inefficiencies, and recommends adjustments to reduce consumption without impacting output.

Operators gain:

- Lower bills through more efficient operation schedules;

- Reduced environmental footprint by cutting unnecessary power consumption;

- Identification of equipment that’s consuming excessive energy.

Regulatory & Compliance Automation

Constant reporting requirements across multiple jurisdictions are another common challenge. With an LLM-powered application, document generation can be automated, regulatory changes tracked, and submissions kept up to current standards with ease.

Benefits include:

- Faster completion of mandatory reports that previously required days of manual work;

- Decreased risk of penalties from missed deadlines or incorrect formatting;

- Automatic updates when regulations change, without retraining staff on new procedures.

Workforce Training and Knowledge Mining

Experienced engineers and field technicians retire, taking decades of operational knowledge with them. Generative AI in oil and gas industry captures this expertise by analyzing maintenance logs, incident reports, and documented procedures. The systems then generate educational materials, troubleshooting guides, and decision-support tools for newer employees.

This technology enables:

- Faster onboarding for new hires who can access institutional knowledge through AI assistants;

- Preserved expertise from retiring workers that would otherwise be lost;

- On-demand guidance for techs dealing with unfamiliar equipment issues.

Environmental Impact Monitoring

Tracking emissions across thousands of facilities requires constant supervision. Artificial intelligence can process all available data to calculate carbon footprints and identify emission sources. The technology flags anomalies that might indicate leaks or inefficient combustion.

Companies benefit from:

- Accurate reporting that meets increasingly strict regulatory requirements;

- Early detection of methane leaks that both harm the environment and waste products;

- Evidence-driven insights for reducing carbon intensity.

While these are common applications, each company faces unique challenges. What works for one business might not address your specific pain points at all. Luckily, with experienced Generative AI developers, you can build a custom tool that tackles exactly what’s slowing you down.

The real question is whether these implementations actually deliver the returns companies expect. Let’s look at what the data shows.

What Benefits Does Generative AI in Oil and Gas Industry Actually Deliver?

The numbers from early implementations show consistent patterns across different functions. Businesses employing AI-enabled asset integrity and reliability programs achieve a 50% drop in incidents. Methane reduction of 40% is possible by 2030, reaching 73% by 2050.

IBM’s research on Generative AI implementation in oil and gas reveals improvements across three key areas:

- Production and output: 27% rise in production uptime, 26% better asset utilization, and 15% growth in throughput.

- Operational performance: 18% increase in employee productivity, 15% decline in capital expenditure, and 18% fall in expenses.

- Safety and sustainability: 22% improvement in energy efficiency, 15% less carbon emissions, and 29% decrease in incidents.

Firms taking full advantage of artificial intelligence can deliver incremental profits reaching 30% to 70% of their earnings before interest and taxes over the next five years. Quick wins come from automating simple tasks like troubleshooting equipment issues or streamlining reporting processes, which immediately boost productivity by 10% to 15%.

Industry-wide averages are useful, but individual case studies demonstrate what works in diverse contexts. Here’s how this plays out in practice.

What Successful Generative AI Applications in Oil and Gas Industry Look Like?

Conversational Data Analysis for Energy Management

An energy and carbon management company needed to give non-technical employees access to complex databases without SQL expertise. Dependence on their IT department created delays in decisions.

Our team developed a chat-based tool where users type questions in plain English. The algorithm translates queries into SQL, executes them securely, and presents results through automatically selected charts. Workers can download data in CSV format for reports.

Results: Business teams gained instant data access without IT support, accelerating decision-making while maintaining strict security controls.

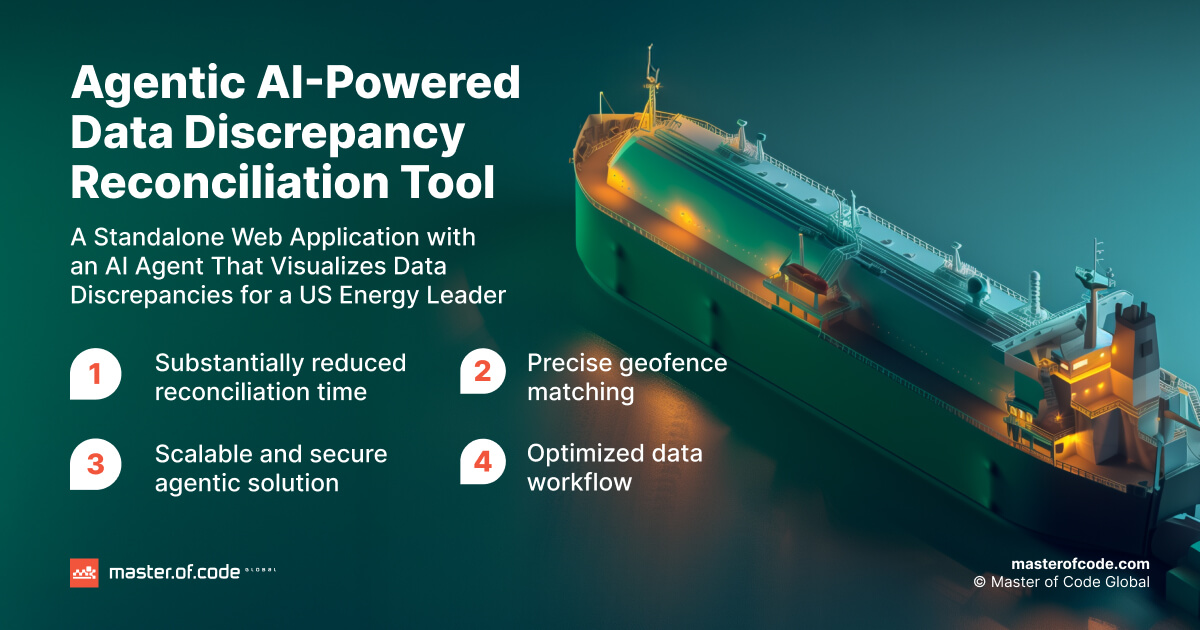

Data Discrepancy Reconciliation

A US energy company struggled with inconsistencies between water and oil readings. Manual reconciliation took hours and increased reporting errors.

Master of Code Global built a web application with an AI agent that automates detection and explains discrepancies in plain language. Using Azure Cognitive Services with GPT-4o-mini, the system flags issues and provides clear explanations: “The reported offload differs from the hauler volume by more than the acceptable 2.7% threshold.”

Results: Automation eliminated hours of manual work while geofencing verification prevented source/destination errors.

Chevron

Chevron launched ApEX for deepwater exploration, where explorationists enter queries into a chat interface and multiple specialized AI agents search through over 1 million files to deliver relevant answers in seconds. Traditional oil and gas prospecting required manually searching through surveys, well logs, maps, and technical reports.

Results: Faster access to previously difficult-to-find data helps Chevron make smarter investments.

BP p.l.c.

BP developed Optimization Genie to uncover hidden production opportunities by examining digital twin models. The AI identifies adjustments to equipment and processes, which engineers then evaluate for safety and feasibility before implementation.

Results: At BP’s Atlantis hub in the Gulf of America, the tool identified changes that increased production by approximately 2,000 barrels per day.

How Should Oil and Gas Companies Approach GenAI Implementation?

You’ve seen what others achieved. Now the question becomes: how do you take it to the next level in your own facilities? Here are a few practical recommendations:

Start Small and Validate First

- Launch with a proof of concept, not full deployment. An AI PoC typically costs $10,000–$20,000 and runs 3–4 weeks, revealing technical blockers and data gaps before major investment. Plus, you get the use cases validated first.

- Pick one high-impact problem where manual work creates the most friction or cost. Don’t try to automate everything at once.

- Define measurable success criteria upfront: “reduce reconciliation time by 50%” or “cut unplanned downtime by 20%.” Vague goals like “improve efficiency” never deliver clear returns.

Assess Your Foundation

- Audit your data before building anything. GenAI depends entirely on information quality and accessibility. Companies often discover data lives in silos, lacks proper labeling, or doesn’t meet compliance requirements.

- Check infrastructure readiness. Can your systems integrate with AI tools through APIs? Do you have secure access to operational databases?

- Establish clear ownership for the AI initiative. Without executive sponsorship and cross-departmental alignment, projects get stuck in pilot purgatory.

Choose the Right Partners

- Cooperate with Generative AI consultants who understand your sector. Energy processes have unique requirements around safety, compliance, and uptime that generic solutions don’t address.

- Ensure they offer post-deployment assistance and optimization. Intelligent applications need continuous monitoring, retraining, and refinement as your operations evolve.

- Prioritize partners who design for integration from day one. Solutions must work with existing ERP, SCADA systems, and proprietary databases.

Design for Augmentation, Not Replacement

- Build systems that support human expertise rather than replacing it. AI in energy sector should make data more accessible and decisions better informed.

- Implement human-in-the-loop workflows for high-stakes cases like safety protocols or major operational changes.

- Focus on transparency and explainability so teams understand how the algorithm works.

Plan for Scale

- Start with a pilot in one facility or operation before rolling out company-wide.

- Document what works and what doesn’t during early implementations.

- Build modular systems that can expand to other use cases as you gain confidence and experience.

Address Compliance Early

- Ensure AI solutions meet industry regulations from the start, not as an afterthought.

- Implement proper data governance, access controls, and audit trails.

- Consider privacy requirements, especially when dealing with operational data that could reveal competitive information.

This approach reflects what we’ve learned from working directly with oil and gas companies. As one of our project managers who specializes in upstream implementations explains:

“In the energy industry, especially in the upstream sector, the greatest value of AI solutions isn’t mere automation, but enhanced predictability. Companies operate in a high-risk environment, and any technological implementation must be as transparent and verifiable as possible. The right approach is to build systems that don’t replace experts, but augment their capabilities, making data more accessible and decisions better informed.”

What’s Next?

Generative AI in oil and gas industry isn’t a distant future; it’s already delivering results. Now imagine bringing it into your own operations: a 27% increase in production uptime, 18% higher employee productivity, and up to 29% fewer incidents. Not bad for a single implementation.

So how do you get there?

Explore our Generative AI integration services, fill out the form with your request, timeline, and needs, and we’ll take it from there. Our team will assess the best technical approach, walk you through each step so you stay fully informed, and then move into implementation.

Straightforward, transparent, and built around your goals. Let’s get started.