The vehicle industry thrives on precision and efficiency. Yet, too often, operations are crippled by unforeseen roadblocks. Unplanned downtime halts production lines, supply chain disruptions ripple through the entire ecosystem, and quality control issues lead to costly recalls and reputational damage. The financial fallout is substantial: lost revenue bleeds from every minute of inactivity, operational costs skyrocket, and critical deadlines vanish in the rearview mirror. This isn’t just a minor inconvenience; it’s a major drain on profitability, a drain that predictive maintenance AI automotive solutions are designed to address.

Modern systems are awash in data. Sensors, machines, and processes generate a constant stream of information – a treasure trove of insights waiting to be unlocked. The global automotive data management market is expected to reach $8.05 billion by 2030. Despite this growth, such a valuable resource often goes untapped. It’s like having a gold mine and not having the tools to extract the riches within. This unprocessed data holds the key to optimizing performance, but without the right approach, it remains just that: raw potential.

Traditional maintenance strategies, whether reactive or preventative, play a crucial role. Fixing things when they break and scheduling regular check-ups are fundamental. However, today these methods alone are insufficient. They’re a starting point, not the destination. They address the symptoms of operational inefficiencies, not the root causes.

To truly maximize uptime, minimize costs, and optimize performance, we need to embrace AI-powered predictive maintenance for automotive, which enables manufacturers to anticipate failures before they disrupt operations. Intrigued? Let’s explore!

Table of Contents

The AI Advantage: Transforming Data into Actionable Insights

Enter artificial intelligence: the game-changer that finally unlocks the hidden potential within your automotive data. Forget sifting through spreadsheets and struggling to connect the dots. AI’s sophisticated algorithms dive deep into the information deluge, dissecting complex datasets and unearthing hidden patterns and anomalies that would remain invisible to the human eye. This isn’t just about collecting information; it’s about truly understanding it. Applications of AI for predictive maintenance in automotive enable businesses to shift from reactive fixes to proactive, cost-saving solutions.

The true magic of digital tools lies in their uncanny ability to predict. They can foresee potential failures and disruptions before they even begin to materialize, handing you the reins to take preventative action. Also, 47% of global manufacturers currently deploy predictive maintenance technologies to curtail operational expenses, highlighting a significant growth opportunity for the remaining 53% to improve efficiency and reduce costs through advanced maintenance strategies.

Picture this: anticipating a critical part failure on your production line before it cripples your output, or forecasting a supply chain bottleneck weeks in advance, giving you ample time to adjust your course. In fact, preemptive strategy can lead to a 10% to 20% reduction in overall costs and a 50% reduction in unplanned downtime. This is the power that fuels car maintenance predictive analytics, making sure that every component functions at peak efficiency while extending the lifespan of critical automotive parts.

AI acts as the ultimate insight catalyst, transforming a chaotic jumble of raw data points into a goldmine of valuable, actionable intelligence. These insights empower you to make smarter, data-driven decisions at every level. From fine-tuning schedules and refining your supply chain to bolstering quality control and slashing downtime, AI for predictive car maintenance provides the strategic advantage you need to not just keep pace but to surge ahead of the competition.

For example, recently, Master of Code Global collaborated with a leading US dealership that aimed to transform their consumer experience with the power of intelligent tech. We created AI voice agent that has become a strategic partner for the dealership, enhancing customer engagement by handling nuanced requests, scheduling appointments, and proactively following up with buyers. In just two months, it delivered a 37% increase in lead conversions, a 26% rise in test-drive appointments, and 357 successful after-sales engagements, transforming the customer experience and driving measurable business growth.

The ROI Equation: Measuring the Value of Predictive Maintenance

Downtime Reduction

Imagine slashing your operational delay by, say, 20%, 30%, or even more. Think about the impact on your bottom line: fewer lost production hours, reduced idle labor costs, and minimized revenue leakage. That’s not just hypothetical; it’s the tangible result of predictive maintenance in action. In fact, research indicates that AI can reduce expenses by 30-40% compared to reactive strategies, delivering significant cost savings. Consider the potential of reclaiming those lost production hours and turning them into profit-generating activity. The numbers speak for themselves, and Generative AI in automotive is accelerating this transformation by refining predictive algorithms and improving system performance.

Efficiency Gains

But the benefits extend far beyond just minimizing downtime. Predictive maintenance fuels improvements across the entire automotive value chain. From optimizing manufacturing processes and streamlining your supply chain to maximizing the performance of your fleet – the impact is significant. For instance, Volvo Trucks and Mack Trucks have developed a system that collects detailed data, leading to a 70% reduction in diagnostic time for breakdown detection and a 25% decrease in repair time through data analysis. We’ve seen clients achieve double-digit improvements in operational efficiency, translating directly into increased output and reduced operational expenses. These aren’t just vague promises; they’re data-backed results, demonstrating the concrete value of AI in automotive.

Quality Enhancement

Predictive maintenance acts as an early warning system, identifying potential defects and quality issues before they escalate into costly recalls or damage your brand reputation. By catching these problems early in the production process, you can minimize waste, reduce rework, and make sure that every vehicle that rolls off the line meets the highest standards. AI in automotive supply chain guarantees that manufacturers can anticipate logistical disruptions and mitigate risks before they impact end costs. That’s an ROI that goes beyond just the balance sheet – it’s an investment in your brand’s future.

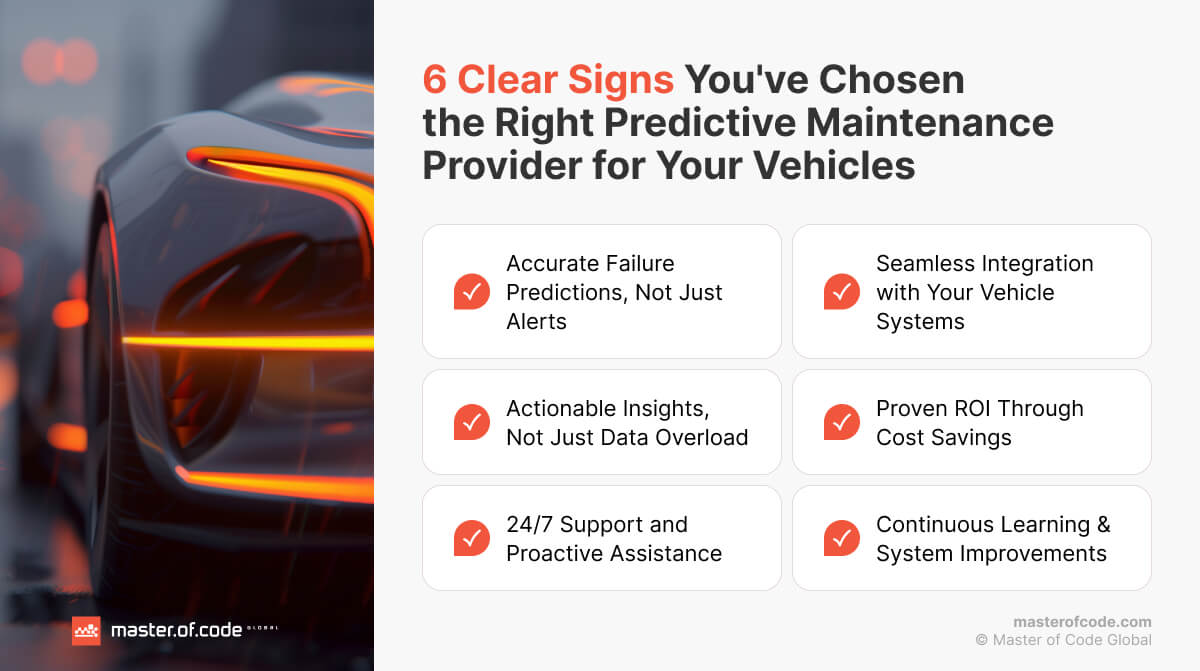

The Strategic Partnership: Choosing the Right Provider

In the race to leverage the power of AI-driven predictive maintenance for automotive, choosing the optimal companion is paramount. It’s about finding the right ally who understands the intricacies of the vehicle world.

Industry Expertise

You need a partner with deep knowledge, someone who gets the unique challenges and opportunities that define this landscape. Generic solutions simply won’t cut it. You need a team that speaks your language and understands your specific needs, from the complexities of manufacturing to the nuances of supply chain management. The vendor should be able to hit the ground running, not spend months trying to understand your business. This is especially critical in AI in automotive manufacturing, where efficiency and precision are essential for success.

Technical Capabilities

Look for a provider with proven expertise in machine learning, a track record of successful implementations, and a commitment to data security. Our ISO 27001 certification, for example, underscores Master of Code Global’s dedication to protecting your information. We understand that your data is your most valuable asset, and we treat it accordingly. Beyond certifications, look for demonstrable experience and a clear understanding of the cutting-edge technologies, including, for example, the specifics of AI in automotive repair, making sure vehicles receive proactive maintenance rather than reactive fixes.

Collaboration and Support

A true partnership is built on communication. You need a provider who listens to your needs, works closely with your team, and gives ongoing support every step of the way. It’s about more than just deploying a solution; it’s about building a long-term relationship based on trust and mutual success. Choose a partner who’s in it for the long haul, assuring you realize the full potential of AI predictive analytics services to maximize efficiency and ROI.

The Implementation Roadmap: From Pilot to Scale

Phased Approach

We advocate for a staged rollout, starting with a strategic pilot project. This allows you to test the waters, validate the solution’s effectiveness in a controlled environment, and fine-tune the system before a full-scale deployment. Think of it as a test drive before you commit to the open road. This minimizes risk and allows for adjustments along the way, confirming that the final strategy perfectly aligns with your operational needs.

Integration and Customization

Seamless incorporation into your existing systems is paramount. We design tailored predictive maintenance AI automotive solutions that integrate smoothly, minimizing disruption and maximizing compatibility. No clunky workarounds or forced migrations. Furthermore, we recognize that every automotive operation is unique. That’s why our methods are highly customizable, adapting to your specific needs and workflows. One size doesn’t fit all, and our approach reflects that reality.

Change Management

But technology alone isn’t enough. Successful implementation hinges on effective change management. Introducing new tools requires careful planning, clear communication, and comprehensive training. We work closely with your team to provide a smooth transition, empowering your employees to maximize their potential. We’re not just giving a solution; we’re building a partnership, affirming that your workforce is equipped for success in the age of predictive maintenance. From pilot project to full production, we’ll be with you every mile of the way, offering the support and guidance you need to thrive.

Your Next Steps

Predictive maintenance isn’t just a futuristic concept. Think of it as your personal key to unlocking unprecedented levels of efficiency, profitability, and quality in the automotive industry today. By harnessing the power of AI, you can transform data from a liability into a strategic asset, turning pain points into profit and raw information into real dollars. Ready to shift your operations into high gear? Contact us today for a free consultation, demo, or strategic session. Let Master of Code Global be your trusted partner on this transformative journey. Let’s build the future of automotive, together.

Ready to build your own Conversational AI solution? Let’s chat!