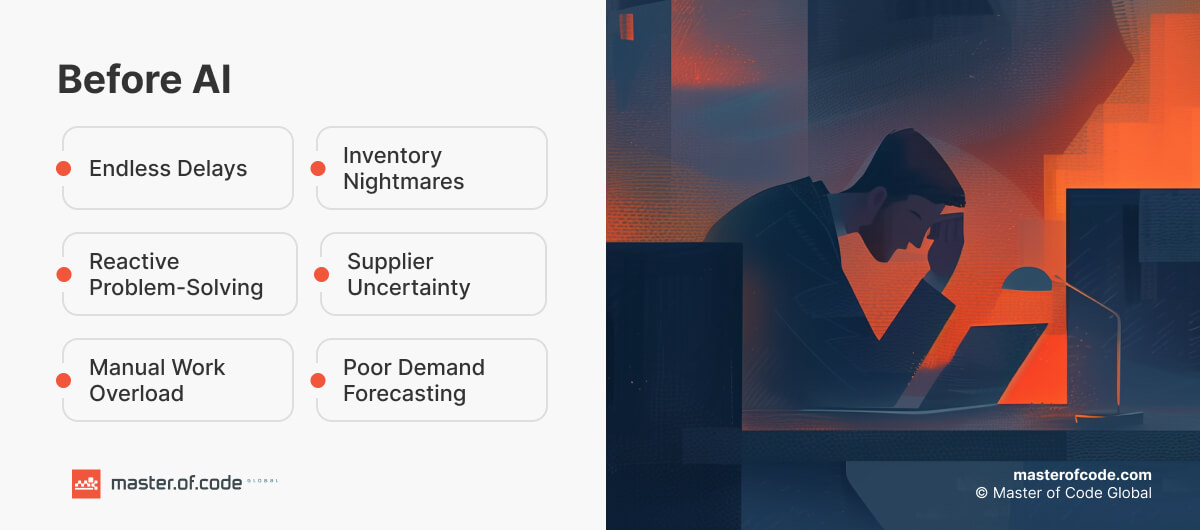

The alarm clock screams. 5:00 AM. Martyn, Supply Chain Director at a major automotive manufacturer, barely has time for coffee before his phone starts buzzing. A critical component is delayed… again. Production lines are at risk. He spends the next few hours in a whirlwind of calls, emails, and frantic problem-solving, trying to avert disaster. By the time the immediate crisis is avoided, another one is brewing – inventory levels are dangerously low for a key model. It’s a relentless cycle of firefighting, a constant battle against unpredictable disruptions. This is the reality for many working without AI in automotive supply chain, a struggle against a system that often feels overwhelming.

This isn’t just Martyn’s story. Across the vehicle industry, managers grapple with the same challenges. Inaccurate forecasts lead to costly overstocking or crippling shortages. Supplier bottlenecks create cascading delays. Logistical nightmares, from port congestion to transportation breakdowns, throw carefully laid plans into disarray. A BCG report indicates that 80% of companies across various sectors remain unprepared to address disruptions quickly and are not structured for long-term resilience.

And all the while, the pressure mounts to keep costs down without compromising quality. Data floods in from every direction, but sifting through the noise to find actionable insights feels like searching for a needle in a haystack. The weight of responsibility is immense; the consequences of failure, significant. Every day is a race against time, a struggle to maintain equilibrium in a system constantly on the verge of collapse. Is there a better way?

Table of Contents

A Shift in Perspective: Introducing AI – The Dawn of a New Day

Artificial intelligence isn’t a magic bullet that instantly solves every supply chain woe. It’s not about replacing human expertise; it’s about augmenting it. Think of AI as a powerful tool, a sophisticated assistant that empowers managers to transcend the limitations of traditional methods and finally gain control. Technology adoption can improve network efficiency by up to 40% through advanced data processing and automation, enabling faster decision-making and proactive problem-solving. Instead of reacting to crises, AI in automotive supply chain management allows you to anticipate them.

Remember those inaccurate forecasts that led to either excess inventory or crippling shortages? A demand foreseeing system analyzes historical data, market trends, and even external factors like weather patterns to generate predictions with unprecedented accuracy.

Martyn can now say goodbye to reactive inventory management. AI in automotive manufacturing optimizes stock levels in real-time, minimizing carrying costs while ensuring you have the right materials at the right time. Those logistical nightmares? The algorithms can map the most efficient routes, predict potential delays, and even automate communication with carriers, streamlining the entire transportation process.

AI sifts through the deluge of data, identifying patterns and insights that would be invisible to the human eye. It transforms raw information into actionable intelligence, giving you a clear, comprehensive view. Early adopters of AI-powered supply chain management have achieved significant gains, for example:

- Reduced logistics costs by 15%

- Cut inventory levels by 35%

- Enhanced service levels by 65%

- Outpaced competitors that have been slower to adapt

This isn’t just incremental improvement; it’s a fundamental shift in perspective. It’s the dawn of a new day for automotive supply chain management. Now, let’s see what that day looks like.

A Day Transformed: The Power of AI in Action

The alarm clock rings. 6:00 AM. Martyn wakes up refreshed. He checks his supply chain dashboard on the tablet while having a tasty breakfast. The digital system has already flagged a potential risk – a minor delay at a supplier in Eastern Europe. But it’s not a crisis. The system has automatically suggested alternative sourcing options and rerouting logistics. Martyn approves the changes with a few taps on his screen. He arrives at the office feeling in control, not consumed by anxiety.This is just one example of how AI automotive solutions can revolutionize daily operations.

Intelligent Process Setup for Morning

Martyn starts his day by reviewing AI-driven demand forecasts. The system has analyzed sales data, market trends, and even competitor activity to project consumption for the next quarter with remarkable accuracy. Digital predictions can reduce errors by 20% to 50%, leading to a 65% reduction in lost sales and product unavailability, making sure that production aligns closely with real demand. Based on this data, the technology has automatically adjusted manufacturing plans, optimizing resource allocation and minimizing waste. Martyn simply reviews and approves these recommendations, freeing up time for more strategic initiatives.

Real-Time Monitoring for Mid-day

Noon brings a flurry of activity, but Martyn remains calm and collected. He monitors logistics and transportation in real-time, thanks to the AI-powered platform. A potential bottleneck at a port is flagged by the system. Before it escalates, the artificial intelligence algorithms suggest alternative routes and automatically notify the relevant carriers. Martyn collaborates with vendors through the same platform, resolving any issues proactively and efficiently.

AI in Supply Chain Analytics for Afternoon

Later, Martyn delves into logistics analysis. The system has compiled and visualized key performance indicators, highlighting areas for improvement. Instead of sifting through spreadsheets, Martyn focuses on interpreting the data and making informed decisions. He identifies opportunities to optimize inventory levels, reduce lead times, and improve supplier collaboration. His day is no longer consumed by firefighting; it’s spent strategically shaping the future of their supply chain. The difference is palpable, and AI in the automotive industry is proving its value across various aspects of the business.

The Ripple Effect: Benefits Beyond Efficiency

The impact of artificial intelligence in supply chain management in the automotive industry extends far beyond simple efficiency gains and cost reductions. In the car sector specifically, AI is poised to revolutionize operations, with the market expected to reach $744 billion within the next decade, underscoring its transformative potential. It creates a chain reaction, transforming the entire organization and driving significant business value.

- Consider employee satisfaction. Supply chain managers like Martyn are no longer burdened by constant firefighting and data overload. They have more time for strategic work, for innovation, and for developing their teams. Reduced stress and increased job enjoyment lead to higher retention rates and a more engaged workforce.

- Customer satisfaction also benefits significantly. AI-powered optimization leads to improved delivery times, reduced lead times, and higher product quality. When the supply chain runs smoothly, clients receive their orders on time, every time, and are happier with the overall experience.

- Furthermore, artificial intelligence fuels business growth. The increased agility and responsiveness to market changes allow companies to seize new opportunities and adapt quickly to shifting demand. Digital insights help identify new markets, optimize pricing strategies, and personalize journeys. This translates into increased revenue and share. Generative AI in automotive can even revolutionize product development, enabling the rapid design and prototyping of new vehicles and components.

- Ultimately, digital tools provide a significant competitive advantage. Brands that embrace AI in their supply chains can achieve faster time-to-market for new products, improve innovation, and outsmart their competitors. They can respond to market changes with unparalleled speed and efficiency, solidifying their position as industry leaders.

Partnering for Transformation: Why Master of Code Global?

We’re not just experts in AI; we’re pioneers in artificial intelligence in automotive supply chain AI consulting. Our specialists understand the unique challenges facing value chain analytics. So, we partner with you to transform your entire work process, from the daily grind to strategic decision-making. The solutions we build are all about reimagining processes, empowering your teams, and fostering a culture of data-driven problem-solving.

Our expertise lies at the intersection of AI and the automotive industry. We’ve helped leading manufacturers optimize their supply chains, reduce costs, and improve satisfaction. For instance, we recently partnered with a major automotive group to revolutionize their online client interaction. We developed an unauthenticated web messaging solution with an FAQ bot powered by Generative AI, capable of handling complex routing for 195 different dealerships.

With a knowledge base covering answers for 14 brand models with 79 variations, this intelligent FAQ bot brings a new level of personalization and efficiency to interactions, guaranteeing a smooth and enjoyable experience for every website visitor. This innovative approach not only optimizes customer help but provides valuable insights into user preferences and pain points, enabling data-driven improvements across the business. We’ve also helped other clients refine their logistics, improve supplier collaboration, and accelerate time-to-market through our AI development services.

At Master of Code Global, every expert works closely with you to understand the specific needs and challenges, so we could tailor our approach to these unique circumstances. Our team of experienced specialists in software for automotive will guide you through every step of the transformation journey, from initial assessment to implementation and ongoing support. We’ll help you navigate the complexities of digital adoption and make sure that you achieve measurable results.

Ready to transform your automotive supply chain and empower your team? Perhaps you’re also interested in exploring how predictive maintenance AI automotive can minimize downtime and maximize efficiency? Book a call with us today to discuss your needs and explore how we can help you achieve the set goals.

Ready to build your own Conversational AI solution? Let’s chat!